One-stop PCBA Manufacturing Service

15 + years

Industry Expertise

30,000 +

Worldwide Customers

99.8 + %

PCBA Quality Rate

7,000 + M²

R&D and Manufacturing Base

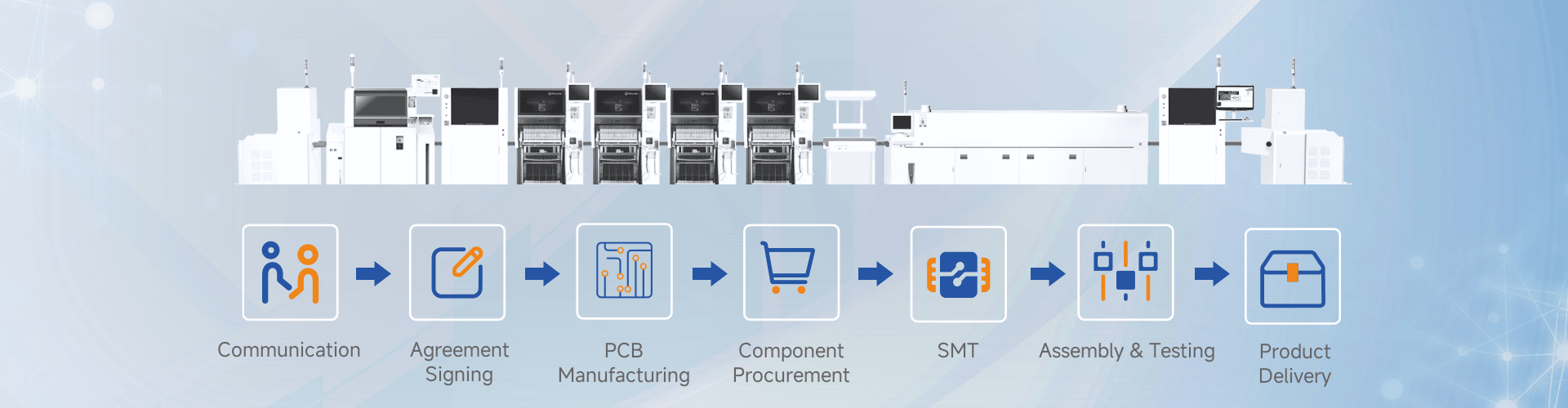

One-stop PCBA Manufacturing Service

DFM (Design for Manufacturing)

Checking for PCB files and BOM parts

PCB Fabrication

for prototype or volume production according to your PCB manufacturing needs

Parts Sourcing

according to specified BOM, supplied from high quality vendors and global distributors, strict inspection and processing

PCBA Processing

Advanced SMT lines, AOI inspection, DIP processing, quality inspection in every step of processing

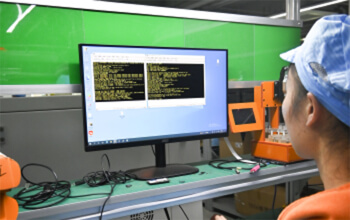

Program Burning and Testing

Make FCT test fixture according to test points, program and test steps designed by customers, and provide program burning and FCT testing services

High Temperature Aging Test

Equipped with high temperature aging equipment, can provide the maximum 80℃ batch aging conditions

Conformal Coating

Equipped with automatic coating production line for PCBA coating and infrared curing

Finished Product Assembly

Provide in-line assembly to deliver a finished product to you to fit your exact requirements with strictly controlled production efficiency

High-quality Supply Chain System Starts from the Quality of Components

With more than 10 years of industry experience, MYIR has a senior supply chain management team and professional engineer teams to help customers with BOM materials supply, component selection and replacement materials recommendation. We have also developed solid relationships with the original factories and agents to ensure the parts are original and authentic with fair prices. The components are stored in anti-static environment with constant temperature and humidity and first-in first-out control mechanism is adopted by the warehouse. MYIR has provided a high-quality supply chain system to ensure that customers can be guaranteed with short delivery time, good quality and low price.

1,000+ Original Manufacturers and Agent Cooperation Partners

(including some of them)

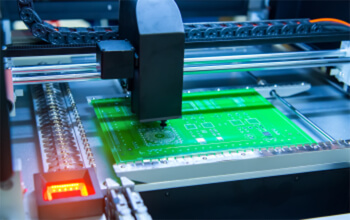

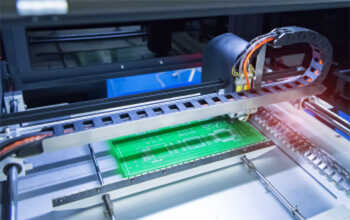

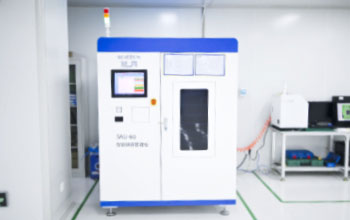

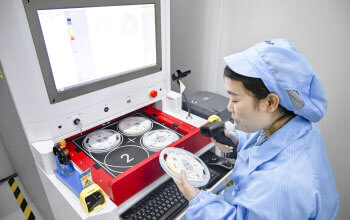

Advanced Equipment to Meet High-precision Production

To provide customers with the highest quality products and services, MYIR has established a ten-thousand-level dust-free production workshop within its smart factory. This workshop is equipped with Panasonic high-speed dual-track SMT lines and a full range of equipment, including automatic solder paste printers, nitrogen convection ovens, wave soldering machines, AOI, SPI, X-RAY, intelligent first-piece inspection machines, intelligent solder paste management cabinets, fully automatic PCB Router Machines, automatic coating equipment, laser engraving machines, BGA repair stations, and more. Furthermore, it features MES intelligent management systems, intelligent storage systems, ERP systems, and static electricity management systems.

Solder Paste Printer

3D SPI

Panasonic NPM-D3A SMT Machine

Panasonic NPM-TT2 SMT Machine

3D AOI

SMT Reflow Oven

First Article Inspection Machine

X-ray

Laser Engraving Machine

Wave Soldering Machine

Automatic PCB Router Machine

BGA Rework Station

Strict Quality Control, Strive for Excellence in Production Process

MYIR has implemented a series of inspection steps, including incoming inspection of materials, pre-assembly baking, solder paste printing inspection, online AOI, first article inspection, spot X-RAY inspection, IPQC patrol inspection, and QA outgoing inspection. We also conduct comprehensive real-time electrostatic protection monitoring. By adhering to the ISO9001 quality management system, we ensure a high product qualification rate for all outgoing products.

Solder Paste Storage Cabinet

X-ray Component Counter

Drying Oven

Constant Temperature Humidity Curing Cabinet

Temperature And Humidity Monitor

ESD Turnstile Gate

Automatic Image Measuring Instrument

Smart Shelf

Advanced Equipment, Exquisite Technology and Fast Delivery

Standard

IPC-A-610HComponent Packaging

Reel, Tape, Tube, Tray, Bulk Packaging is accepted for DIP componentsOrder Quantity

>=1pcPlacement Accuracy

±40μm/chipDelivery Time

The earliest deliver is in 24 hours after all materials availablePCB Size

50 x 50mm ~ 450 x 340mm,PCB size less than 50 x 50 mm must use panelized PCBsAssembly Type

Single or Double sides, Shielding cover if neededPCB Material

soft PCB, soft and hard combined PCB, Spray Tin PCB, Plating gold PCB, Immersion silver PCB, Aluminum PCB, Rubber PCBs, FR-4 PCBMinimum pitch of Component

BGA: 0.3mmTypes of Soldering

lead-free reflow soldering, lead-free wave soldering and hand solderingMinimum Component Size

03015 (Metric)Steel Mesh

Laser Cut PCB Stainless Steel MeshMaximum Component Size

L150*W25*T30mmInspection System

AOI (100%), X-Ray (random sample inspection)SMT Capacity

5.5 million points per dayOther Processes

IC Programming, Function Test, Conformal Coating and Finished Products Assembly