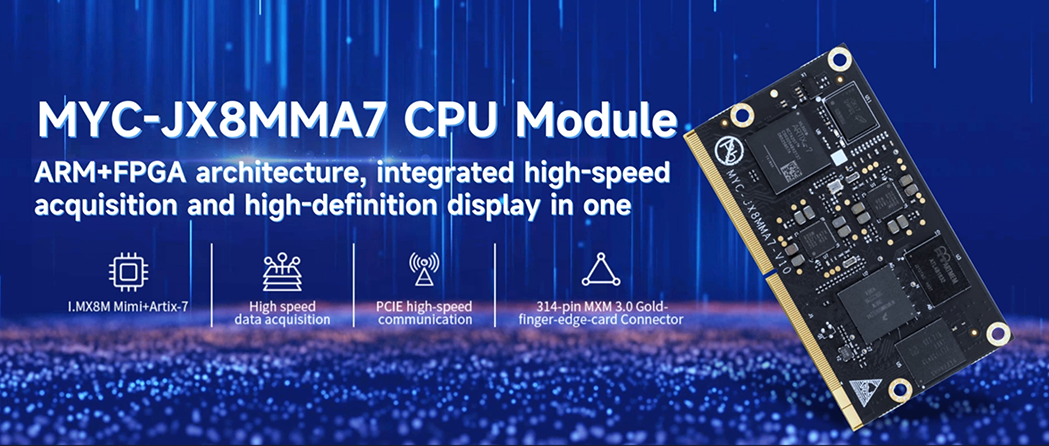

Industrial Data Acquisition Applications Utilizing MYIR's MYC-JX8MMA7 ARM+FPGA SOM

2023-04-13

3938

With the development of communication and network technology and the Internet, the digitization, networking, and intelligence of industrial management have become an inevitable trend. The use of industrial Internet of Things (IoT) to complete industrial control is an essential part of smart factories. Traditional control and data acquisition systems struggle when the host needs to maintain high-speed communication with multiple data acquisition devices simultaneously, and undertake more complex data processing, while maintaining high-definition multimedia display functions, etc. The traditional industrial data acquisition hardware system falls short. However, embedded systems based on ARM and FPGA architectures, which come with rich peripheral interfaces, has high-definition display, and high-speed transmission capabilities, can also perform high-speed industrial data acquisition tasks in parallel. They are one of the essential choices for hardware upgrades in Industry 4.0.

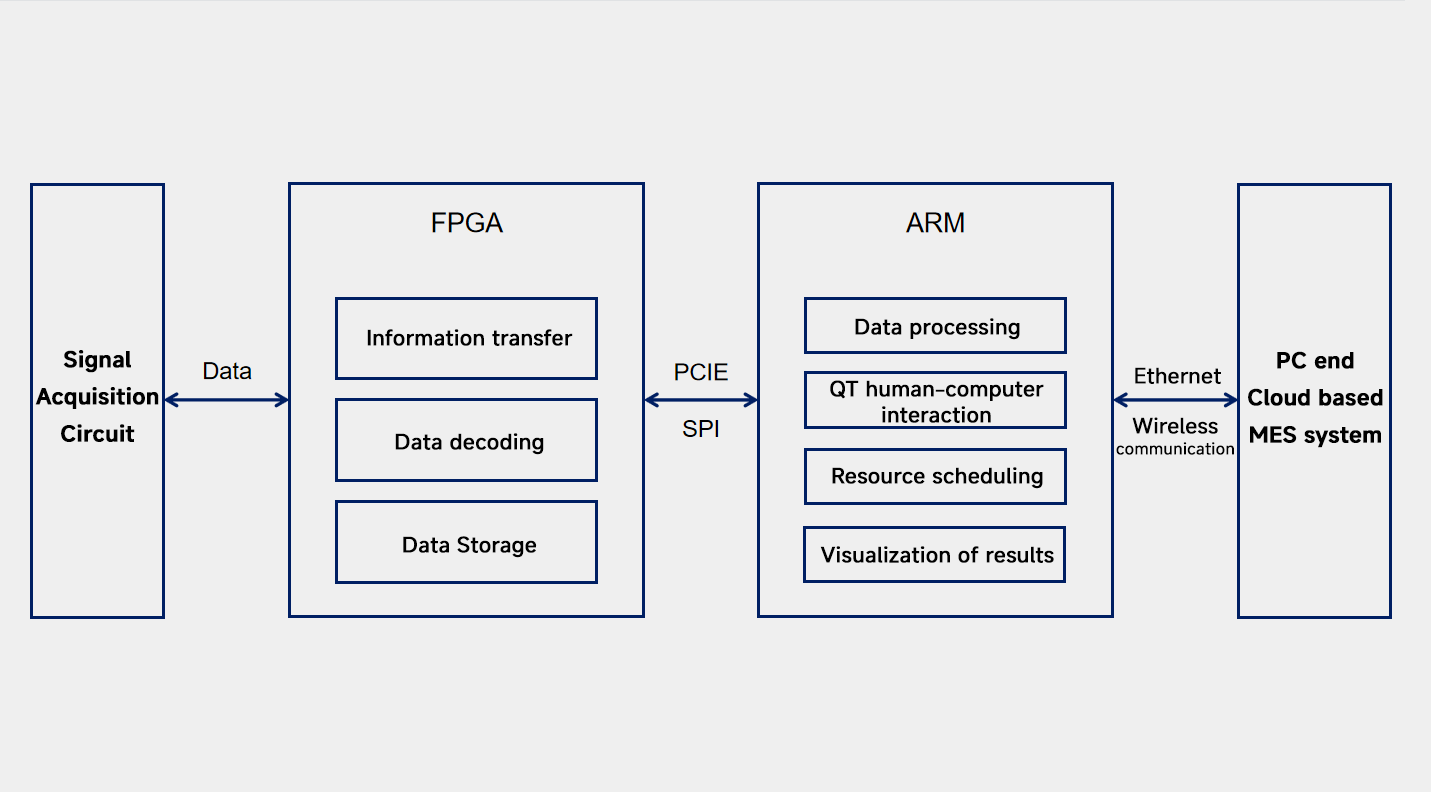

The industrial data acquisition and control system mainly consists of two major structures. The first is the data acquisition system, which primarily uses FPGA processors for high-speed acquisition and obtaining of industrial protocol data; the second is the embedded control platform, which mainly uses ARM processors as the main control center for coordinating and managing the modules, resource scheduling, and at the same time receiving the data from FPGA, result visualization, and human-computer interaction. Using communication modules, the acquired data is transmitted to industrial MES+ERP systems, which not only reduces the risk of manual data entry but also saves on human resources.

Industrial Data Collection and Control System - Framework Diagram

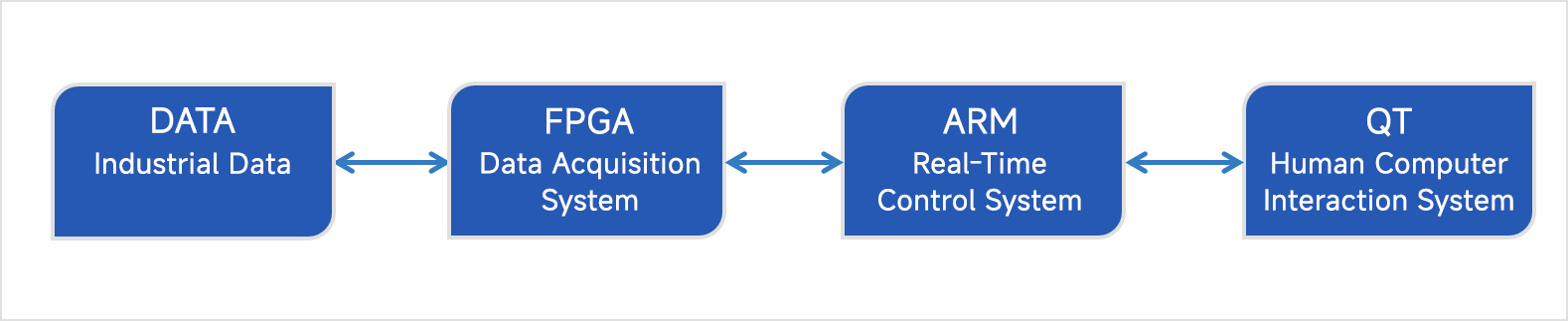

The industrial data acquisition and control system can be mainly divided into high-speed data acquisition system and embedded human-computer interaction system. The two major systems are important components of the industrial automation data acquisition system and are essential industrial systems for upgrading to Industry 4.0.

Industrial Data Collection and Control System - Process Diagram

High speed data acquisition system: The high-speed data acquisition system composed of FPGA chip and industrial signal acquisition system is an important way to quickly obtain industrial information data. Through various external data acquisition modules such as cameras, displacement sensors, high-precision ADC sampling modules, etc., FPGA chips perform parallel sampling processing and storage of the data signals from each module. Thus achieving high-speed industrial data acquisition function.

Embedded human-computer interaction system: As the core of the entire system, the human-computer interaction system sends acquisition command signals to the signal control system FPGA for data acquisition through SPI/PCIe. After data acquisition and processing, it is uploaded to the ARM chip for data processing and analysis through SPI/PCIe. On the other hand, it is possible to connect a mouse and keyboard via USB, manually input commands, perform script based automatic data capture, and display data results through a touch display system; Industrial MES+ERP systems can also be uploaded through the network for cloud storage of industrial data.

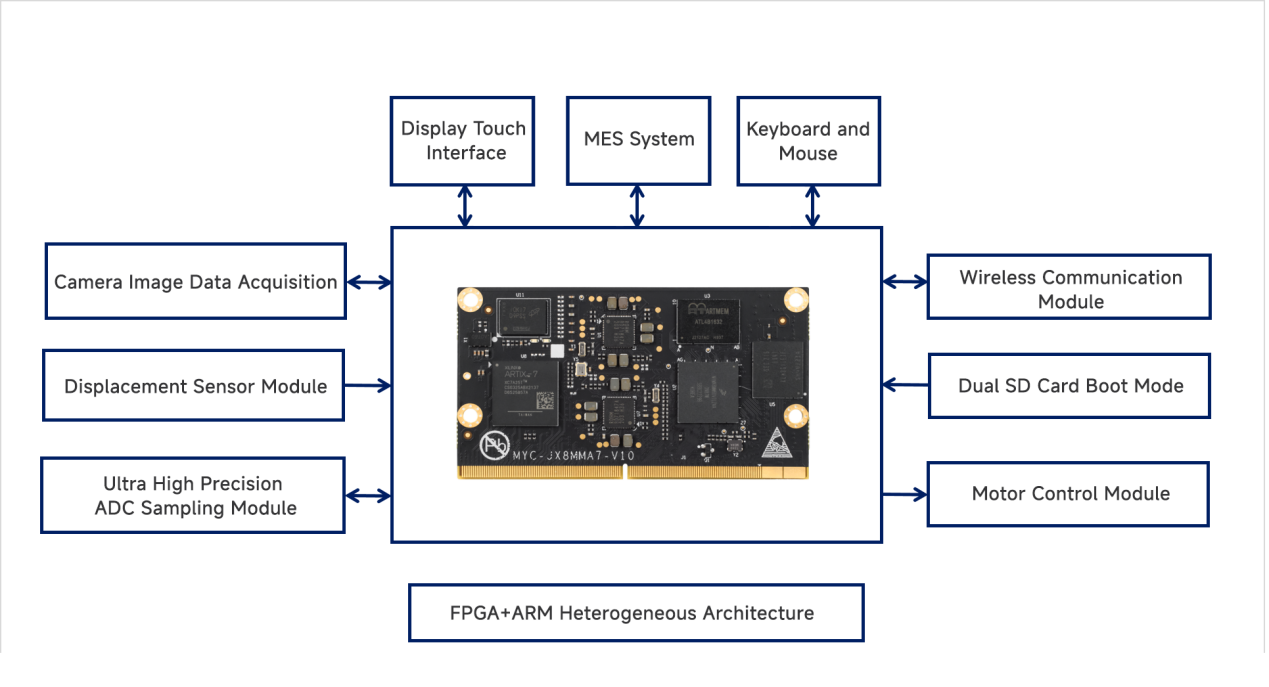

Industrial Data Acquisition and Control System Diagram Based on MYC-JX8MMA7

MYIR’s MYC-JX8MMA7 System-On-Module (SOM) offers an excellent solution for industrial data acquisition and control systems. Featuring an FPGA+ARM heterogeneous architecture, it can greatly reduce hardware costs and design complexities for customers, while providing abundant development resources to accelerate the product development process.

Meet the requirements of high-speed data acquisition

The MYC-JX8MMA7 SOM is equipped with Xilinx Artix-7 FPGA resources that benchmark against Zynq 7010, meeting the high-speed data acquisition needs of the system.

Excellent human-computer interaction and real-time control functions

The NXP i.MX8M Mini processor, which is used on the MYC-JX8MMA7 SOM, features 4 Cortex-A53 cores and a Cortex-M4 core, providing excellent data processing capabilities and a human-computer interaction interface. It is also capable of controlling the motor drive module in real time, fulfilling the data processing, task scheduling, and human-computer interaction requirements of the real-time control system.

High speed communication capability

The MYC-JX8MMA7 SOM, featuring an MPU and a FPGA, use PCIe high-speed communication with a capability of up to 200-300 MB/S to meet the fast data transmission requirements.

To facilitate developers in conducting preliminary functional evaluations and software debugging, MYIR has also developed the MYD-JX8MMA7 development board to assist in product development.

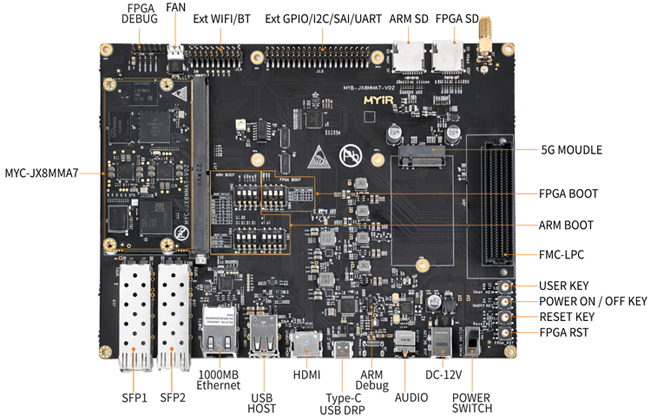

Top-view of MYD-JX8MMA7 Development Board

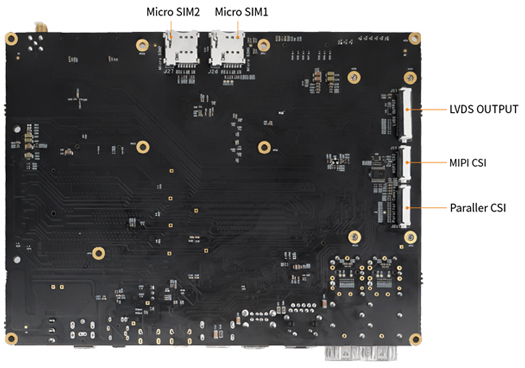

Bottom-view of MYD-JX8MMA7 Development Board

Peripherals and Signals Routed to Pins

0.5mm pitch 314-pin MXM 3.0 Gold-finger-edge-card Connector

ARM

- 1x RGMII

- 2x USB2.0

- 1x MIPI CSI

- 2x SDIO

- 4x UART

- 2x I2C

- 3x SPI

- 1x MIPI DSI

- 3x I2S

FPGA

- 3x GTP

- 23,360x Logic Cells

- 3,650x Slices

- 29,200x CLB Flip-Flops

- 80x DSP Slices

2024-10-12

Application of MYIR's i.MX 6ULL SOM in Teaching Devices

With the development of robotics technology, the application of robots in social production has been promoted. However, the application of robots face some issues such as difficulties in development a

2024-09-25

Application of MYC-Y6ULX-V2 System-On-Module in Motion Control System

With the continuous trend of automation from semi-automatic to fully automatic, the whole industry’s requirements for the "brain" of automation - control system are increasingly high, not on

2024-06-25

EtherCAT Master Controller Solution Based on Remi Pi

EtherCAT is a real-time industrial Ethernet technology proposed by the German BECKHOFF company in 2003. It has the characteristics of high speed and high data efficiency, and supports multiple device

2023-03-21

Application of MYC-Y6ULX-V2 System-On-Module in Mechanical Intelligent Controllers

In recent years, with the development of information technology, the requirements for industrial intelligence and intelligent construction machinery have also been increasing, leading to a growing dem

2023-02-18

EtherCAT Master Controller Solution Based on MYIR's Allwinner T507-H SOM

EtherCAT is a real-time industrial Ethernet technology proposed by the German BECKHOFF company in 2003. It has the characteristics of high speed and high data efficiency, and supports multiple device