Application for Battery Testing Equipment Based on MYIR’s MYC-YA157C-V3 SOM

2022-12-17

2749

Battery Testing Equipment plays a crucial role in supporting the research and development of battery products, driving technological innovation, and ensuring product quality. It is a key strategic instrument in promoting basic research on battery materials and supporting the development of the battery industry.

Using battery testing equipment to detect the battery performance allows for a clear understanding of critical parameters such as current, voltage, cycle life, and internal resistance, among other. By analyzing this information, we can assess the battery's specific conditions to determine if they meet your requirements. If the criteria are met, production can continue; if not, timely measures can be taken to update and rectify issues until the product meets the necessary standards. Additionally, this testing can reveal any shortcomings of the battery, ensuring that only products that meet quality standards are sold to consumers, which enhances safety.

A qualified battery testing device must quickly and accurately measure the operating status of the battery. Through online testing, it can display and record multiple groups of critical battery parameters, including voltage, internal resistance, and interconnect bar resistance. It can accurately and effectively determine the quality of the battery. It can also be used with computers and dedicated battery data analysis software to form an intelligent testing device, further tracking the degradation trends of battery and alerting in advance to enable engineering and management personnel to take appropriate actions.

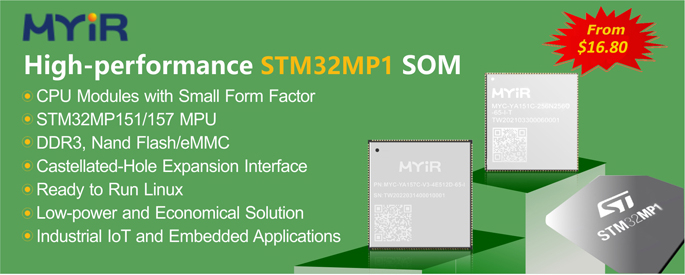

The MYC-YA157C System-On-Module (SoM) from MYIR, featuring the STM32MP157 processor from the STM32MP1 series, offers an excellent solution for battery testing equipment applications. It includes dual Cortex-A7 cores running at 650 MHz, a Cortex-M4 core at 209 MHz, a 3D graphics processing unit (GPU) and an LCD-TFT display controller. This provides customers with a cost-effective development solution, equipped with rich interface resources to facilitate application expansion.

Features of MYC-YA157C-V3

Mechanical Parameters

Dimensions: 45mm x 43mm

PCB Layers: 8-layer design

Power supply: 5V/0.5A

Working temperature: 0~70 Celsius (commercial grade) or -40~85 Celsius (industrial grade)

Processor

STMicroelectronics STM32MP157AAC3 Microprocessor

- Up to 650MHz dual-core Arm Cortex-A7 32-bit RISC core

- Up to 209MHz Arm Cortex-M4 32-bit RISC core with FPU/MPU

- Integrated 3D GPU

Memory and Storage

512MB DDR3 (supports up to 1GB DDR3)

4GB eMMC Flash (supports up to 64GB eMMC)

Nand Flash (alternative design with eMMC, supporting 256MB / 512MB /1GB Nand Flash)

Peripherals and Signals Routed to Pins

One 10/100/1000M Ethernet PHY

1.0mm pitch 164-pin stamp hole expansion interface

- 8x Serial ports

- 6x I2C

- 6x SPI

- 1x SAI

- 1x USB 2.0 Host and 1 x USB 2.0 OTG

- 2x SDIO

- 2x CAN

- 1x MIPI-DSI

- Digital Camera Interface (DCMI)

- RGB Interface (supports RGB888, resolution up to 1366 x 768 @60fps)

- Up to 97 x GPIOs

Note: the peripheral signals brought out to the expansion interface are listed in maximum number. Some signals are reused. Please refer to the processor datasheet and SOM pin-out description file.

OS Support

Linux 5.4.31

Ubuntu 18.04

2024-09-23

BMS Solution based on MYIR's STM32MP1 SOM

Here we will introduce MYIR's battery management system (BMS) solution based on MYC-YA157C CPU Module which is a compact ST STM32MP1 powered System-on Module (SoM) targeting applications like indu

2022-12-17

AC Charging Pile Solution Based on MYIR’s MYC-YA15XC-T System-On-Module

Electric vehicles (EVs) have always been regarded as the next generation of automobiles. With the rise of EVs, the demand for charging piles is also set to experience large-scale industry development.